PressPro™ Dual Flat Heating Plate Automatic Hot Press Machine

PressPro™ Dual Flat Heating Plate Automatic Hot Press Machine

Product Detail

- Product Composition

- Main Machine

- Die Molds- Optional and customizable, not included.

Photo of Hot Press Machine – EPHPAZ01, EPHPAZ02 Series

Photo of Hot Press Machine – EPHPAZ03, EPHPAZ04 Series

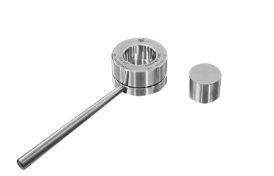

Example Photo of Mold (Optional, not included)

Product Features

The machine uses electric hydraulic drive and an integrated structure. The upper heating plate is fixed, the temperature control system and pressure system have been upgraded again, the program control capability has been greatly improved, and multiple safety features have been added, making it suitable for high-end laboratories.

Product Specifications

|

Product Name |

PressPro™ Dual Flat Heating Plate Automatic Hot Press Machine |

||||||||||||||

|

Model |

EPHPA-Z01

|

EPHPA-Z02

|

EPHPA-Z03

|

EPHPA-Z04

|

EPHPA-ZG1

|

EPHPA-ZG2

|

EPHPA-ZG3

|

EPHPA-ZG4

|

|||||||

|

Pressure Range |

0-25T/0.01t |

0-30T / 0.01t |

0-50T / 0.01t |

0-25T/0.01t |

0-30T / 0.01t |

0-50T / 0.01t |

|||||||||

|

Piston Diameter (mm) |

Ø95 |

Ø110 |

Ø130 |

Ø95 |

Ø110 |

Ø130 |

|||||||||

|

Pressurization Method |

Automatic pressurization / automatic gradual pressurization

|

||||||||||||||

|

Sample Pressure Process |

Automatic pressurization – Automatic pressure holding – Precise pressure compensation – Timed pressure release |

||||||||||||||

|

Pressurization Stages |

5 stages |

||||||||||||||

|

Pressurization Time |

Unlimited seconds, configurable per stage |

||||||||||||||

|

Mold Pressure Conversion |

Real-time automatic calculation of sample pressure (MPa) |

||||||||||||||

|

Control Interface |

7-inch touch LCD screen (remote control optional, not included) Pressure display - Temperature control system – Data management system |

||||||||||||||

|

Temperature Control System |

Programmable with 5-stage heating – Automatic heating and insulation – Natural cooling |

||||||||||||||

|

Insulation Time |

Unlimited seconds, configurable per stage |

||||||||||||||

|

Hot Pressing Plate Type |

Dual flat plate heating and pressing, upper plate suspended by threaded rod/polished surface plate. |

||||||||||||||

|

Heating Temperature |

Room temperature to 300℃ (0.1℃ increments) |

Room temperature to 500℃ (0.1℃ increments) |

|||||||||||||

|

Heating Core Material |

Aluminum |

Copper |

|||||||||||||

|

Hot Pressing Plate Cooling Method |

Natural cooling (optionally available with air/water cooling chiller, not included in standard unit) |

||||||||||||||

|

Insulation Method |

Imported insulation plate |

Imported insulation plate + stainless steel water-cooled insulation plate |

|||||||||||||

|

High-temperature Safety Configuration |

When mold temperature exceeds 50℃, temperature controller automatically signals “Caution: Hot Surface” |

||||||||||||||

|

Power Supply |

220V (50Hz/60Hz) with leakage protector |

||||||||||||||

|

Hot Pressing Plate Size |

180×180mm |

200×200mm |

300×300mm |

400×400mm |

180×180mm |

200×200mm |

300×300mm |

400×400mm |

|||||||

|

Workspace |

W 180×65 mm |

W 200×65 mm |

W 300×65 mm |

W 400×65 mm |

W 180×65 mm |

W 200×65 mm |

W 300×65 mm |

W 400×65 mm |

|||||||

|

Maximum Power |

2200W (900W*2+100W+300W) |

2800W |

5400W |

2200W (900W*2+100W+300W) |

2800W |

5400W |

|||||||||

|

Overall Dimensions |

280*420*620 mm |

280*420*620 mm |

400*500*750 mm |

500*600*780 mm |

280*420*620 mm |

280*420*620 mm |

400*500*750 mm |

500*600*780 mm |

|||||||

|

Weight |

150-160kg |

160-170kg |

300-360kg |

400-460kg |

150-160kg |

160-170kg |

300-360kg |

400-460kg |

|||||||

|

Configuration Description |

Includes 1 main machine. Optional, not included: pressure gauge, air/water cooled chiller. Customizable height extension and hot pressing molds according to requirements. |

||||||||||||||

Disclaimer: ACS Material, LLC believes that the information on our website is accurate and represents the best and most current information available to us. ACS Material makes no representations or warranties either express or implied, regarding the suitability of the material for any purpose or the accuracy of the information contained within this document. Accordingly, ACS Material will not be responsible for damages resulting from use of or reliance upon this information.