Single-Crystal Graphene

Graphene is a single layer, two-dimensional crystal allotrope consisting of pure carbon atoms that is only one atom thick, revealing a hexagonal shape resembling a honeycomb. The first method to obtain a single-crystal graphene (SCG) was found by mechanically exfoliating a graphite crystal with adhesive tape and it has been the most efficient way of producing the cleanest, atomically thin nanosheets of layered materials.1 Repeated peeling is necessary but it is not easy to determine the number of peelings that would be required to achieve a monolayer graphene.2 The challenge still remains in producing a large sheet of graphene from a graphite crystal since degradation can occur with electronic properties. Uniform growth of large SCG is difficult to obtain in commercial-level manufacturing for a variety of graphene-based applications.3

The chemical vapor deposition (CVD) method is often used to produce monolayer graphene, but it typically uses multiple crystals that can possess defects and ultimately lowering graphene’s unique properties. Currently, one of the methods of obtaining large SCGs would be to allow one graphene nucleus to grow into a large SCG film, which requires a long time for the growth to complete. More recently, a 1.5-inch SCG has been synthesized with one nucleus compared to the 1.0-inch size that was first achieved on a copper foil. Another technique is to put together multiple, aligned graphene islands into a SCG film that potentially has a scalable production; yet, this method faces different challenges such as difficulties in obtaining proper symmetry and seamless stitching of the well-aligned graphene islands.4 Producing a large area of graphene from a single crystal will be especially rewarding in industrial applications as it lowers the number of defects regarding electronic and mechanical properties. Presently, SCG still remains a challenge but new research is being conducted to synthesize large-scale graphene from a single crystal.

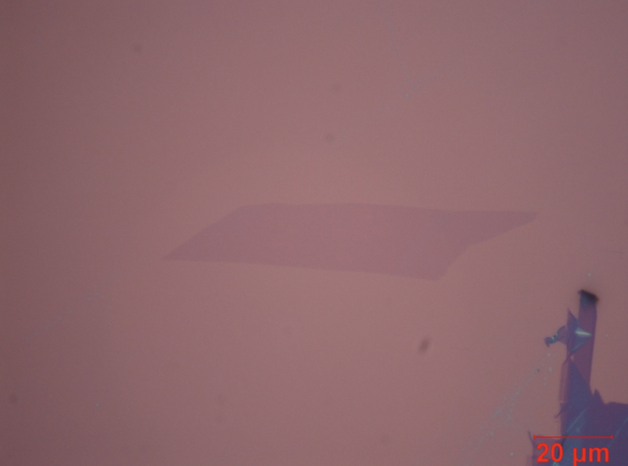

Figure 1. ACS Material's continuous monolayer graphene from a single crystal.

ACS Material provides both monolayer or bilayer options for graphene from a single crystal on SiO2/Si substrate with two different SiO2 thickness [i.e. Mechanically Exfoliated Single Crystal Graphene on SiO2/Si (SiO2: 90 nm or 300 nm thick)]. There are three substrate sizes from which to choose with the graphene area being greater than 5000 μm2. The options come with a 500 μm thickness for the Si substrate and can be applied to various fields such as gas-sensitive materials, biological applications, electronic displays, batteries and composite materials.

ACS Material Products

- Mechanically Exfoliated Single Crystal Graphene on SiO2/Si (SiO2: 90 nm Thick)

- Mechanically Exfoliated Single Crystal Graphene on SiO2/Si (SiO2: 300 nm Thick)

References

1. Li, Hai, et al. “Preparation and Applications of Mechanically Exfoliated Single-Layer and Multilayer MoS2 and WSe2 Nanosheets.” ACS Publications, pubs.acs.org/doi/abs/10.1021/ar4002312. Accessed 18 Sept. 2017.

2. Jayasena, Buddhika, and Sathyan Subbiah. “A novel mechanical cleavage method for synthesizing few-Layer graphenes.” Nanoscale Research Letters, 19 Jan. 2011, doi:10.1186/1556.276X-6-95.

3. Lee, Jae-Hyun, et al. “Wafer-Scale Growth of Single-Crystal Monolayer Graphene on Reusable Hydrogen-Terminated Germanium.” Science, American Association for the Advancement of Science, 18 Apr. 2014, science.sciencemag.org/content/344/6181/286.

4. Xu, Xiaozhi, et al. “Ultrafast epitaxial growth of metre-Sized single-Crystal graphene on industrial Cu foil.” Science Bulletin, vol. 52, no. 15, 17 Aug. 2017, pp. 1074–1080., doi:10.1016/j.scib.2017.07.005.