Si/C Composite Anodes - The New Energy Vehicle Revolution

A lithium-ion battery is one of the most popular energy storage systems in consumer electronic and electric vehicle applications.1 Graphite has been commonly used as an anode material for lithium-ion batteries due to its low and flat working voltage, good cyclability in compatible electrolyte and so on. Its theoretical capacity is limited to 370 mAh/g and volumetric capacity of 830 Ah/L and in order to increase the specific energy of lithium-ion batteries, alternative anode materials with higher capacity are needed.2

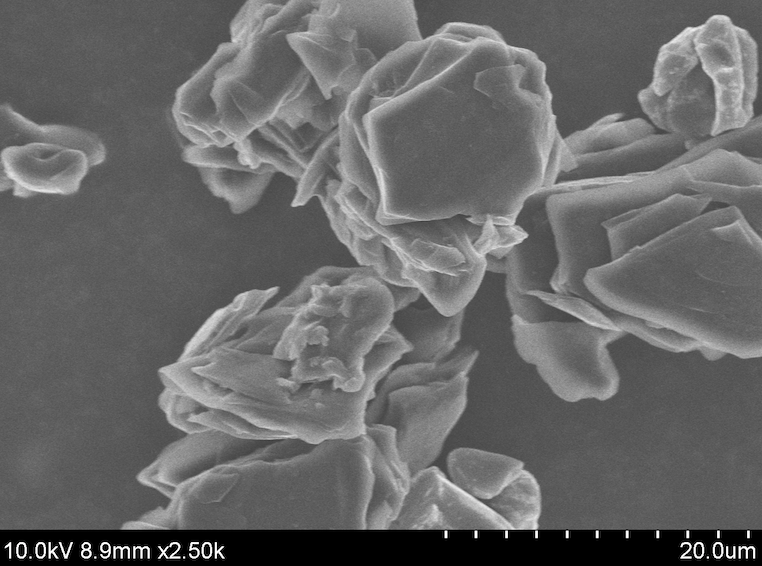

Figure 1. SEM image of a Si/C anode battery of ACS Material.

Silicon has received many attention for its high theoretical capacity (4200 mAh/g) electric potential close to that of carbon and abundant resources.3 However, shortcomings include a limited life cycle caused by volume expansion and high price that hinders its wide application.

For a more efficient development of lithium-ion batteries, anode fabrication is moving away from the use of C or Si to that of Si/C hybrid materials, which are then able to compensate for the limitations related to each of such elements used on its own.4

In the last decade, there are few methods proposed for the production of Si/C composites suitable for the assembling of anodes in Li-ion batteries: 1) Si/C mixing by milling, 2) porous Si/C systems, 3) Si coating of C nanostructures, 4) C coating of Si structures, 5) core-shell Si/C systems and 6) reports in situ characterizations of Si/C hetero materials.4

The theoretical specific capacity of the graphite anode material is 370 mAh/g whereas the graphite anode material with better performance can reach 360mAh/g. However, the Si/C Composite anode materials at ACS Material has the current capacity of these two products at 450 mAh/g and 500mAh/g, respectively, which means that this range can be significantly increased. The cycle performance can reach 1500 weeks while the capacity retention rate can reach 80%. These products have been applied in some well-known factories and achieved industrialization on a bigger scale.

ACS Material also offers high-performance silicon and silicon monoxide nanoparticles. The products with small particle size, high purity and other advantages are favored by customers.

ACS Material Products (Anode Powders — New Battery Materials):

References

1. Sourice J, Quinsac A, Leconte Y, et al. One-step synthesis of Si/C nanoparticles by laser pyrolysis: high-capacity anode material for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2015, 7(12):6637.

2. Yang J, Wang B F, Wang K, et al. Si/C Composites for High Capacity Lithium Storage Materials[J]. Electrochemical & Solid State Letters, 2003, 6(8):A154-A156.

3. Wen Z S, Yang J, Wang B F, et al. High capacity silicon/carbon composite anode materials for lithium ion batteries[J]. Electrochemistry Communications, 2003, 5(2):165-168.

4. Terranova M L, Orlanducci S, Tamburri E, et al. Si/C hybrid nanostructures for Li-ion anodes: An overview[J]. Journal of Power Sources, 2014, 246(3):167-177.