NanoFX™ High Concentration Nano Bubble Generator

NanoFX™ High Concentration Nano Bubble Generator

Product Detail

Product Overview

The equipment is designed based on the principle of high-pressure microchannel turbulence, and the gas source can be connected to oxygen, nitrogen, hydrogen, and other gases externally. It is suitable for use in the ozone oxidation treatment of wastewater, oilfield recovery research, photovoltaic semiconductor cleaning, chemical gas-liquid reactions, and other research projects.

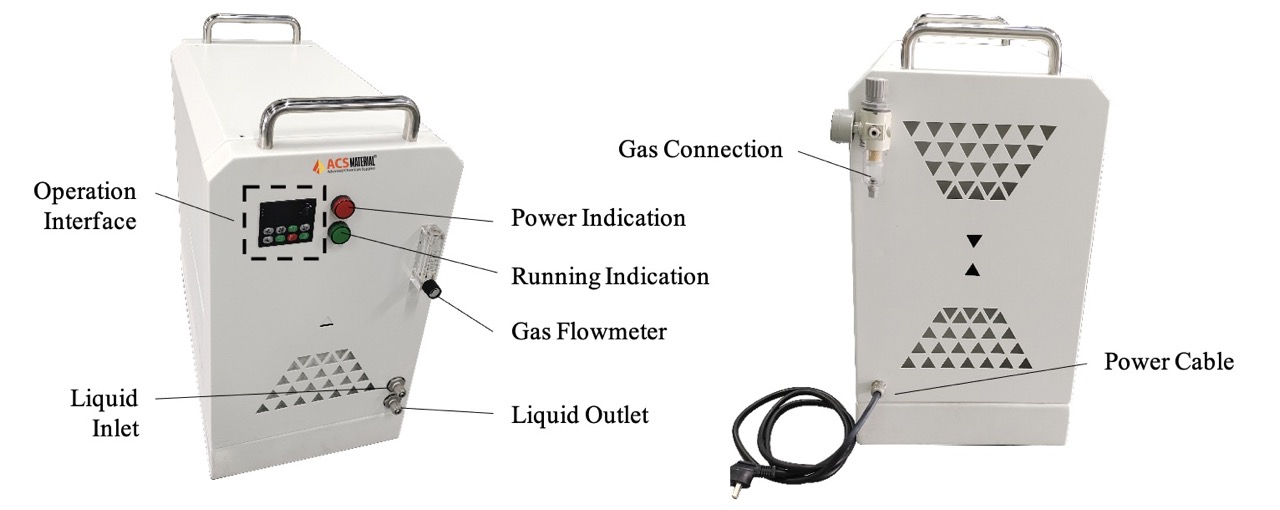

Photos of High Concentration Nano Bubble Generator

Product Features

|

Product Name |

NanoFX™ High Concentration Nano Bubble Generator |

|

Model |

ENNBG001 |

|

Power |

110V 1.5 kW (Customizable according to customer requirements) |

|

Air Inlet Flow |

0-0.8 L/min |

|

Nano-bubble Water Flow Rate |

3 L/min |

|

Nano-bubble Size |

151.7 nm |

|

Nano-bubble Concentration |

280 million particles/mL |

|

Overall Dimensions |

70*45*75 cm |

|

Weight |

~30 kg |

|

Configuration Description |

Includes 1 main machine, hoses for transporting liquids. |

Product Specifications

- High Preparation Efficiency: This equipment can prepare many micro and nano-scale bubbles in a short time through high-pressure turbulent shear technology. It has a flow rate of 3 L/min and a particle size of about 150 nm, with its nano-bubble particle size at 151.7 nm and a concentration of up to 280 million particles/mL, placing it at the industry-leading level.

- Adjustable Frequency: The equipment uses a frequency converter to adjust the frequency, allowing it to produce nano-bubbles while effectively reducing energy consumption and improving operational efficiency. Additionally, the air inlet has a 6mm quick insert, which allows for the introduction of various gases, greatly expanding the device’s range of applications.

- Good Size Uniformity: The equipment can control the size distribution of micro and nano-bubbles by adjusting the shear conditions, ensuring more uniform bubbles.

- High Stability and Mass Transfer Efficiency: The micro- and nano-bubbles generated by the equipment have ultra-high stability and mass transfer efficiency, improving the solubility and stability of air in water.

- Negatively Charged Surface: The micro and nano-bubbles produced by the device have a negatively charged surface, providing strong adsorption capacity for hydrophobic particles and pollutants.

- Generation of Reactive Radicals: Micro and nano-bubbles release chemical energy during the bursting process, generating many reactive free radicals or reactive oxygen species (ROS) radicals.

- Application Areas: The equipment can be widely used in scientific research units, universities, new materials development, biomedicine, and other high-tech enterprises.

- Water Treatment/Environmental Protection: Nano-bubble water treatment and purification.

- Food Additives: Emulsification of milk, soy milk, plant-based drinks, and food additives.

- Microchannel Reactor: Safe and efficient microreactor; continuous synthesis of fruit acids and azo dyes.

- New material Synthesis: Dispersion of nanomaterials, ultrafine powder crushing, and preparation of composite materials.

- Cosmetics: Emulsification and plant extraction.

- Drugs, Pharmaceutical Intermediates: Liposomes, cell fragmentation, plant extraction.

Disclaimer: ACS Material, LLC believes that the information in this website is accurate and represents the best and most current information available to us. ACS Material makes no representations or warranties either express or implied, regarding the suitability of the material for any purpose or the accuracy of the information contained within this document. Accordingly, ACS Material will not be responsible for damages resulting from use of or reliance upon this information.