MCM-48

Product Detail

1. Preparation Method

Hydrothermal Method

2. Composition & Information on Ingredients

Synonym: MCM-48, Porous Silica, Silicon dioxide

CAS Number 7631-86-9

Linear Formula SiO2

Molecular Weight 60.08

EC Number 231-545-4

3. Characterization & Analysis

|

Type: |

A (Discontinued) |

B |

|

Grade: |

Reagent Grade |

Reagent Grade |

|

Appearance: |

White Powder |

White Powder |

|

Particle Size: |

200-400 nm |

200-500 nm |

|

Shape |

Spherical |

Flower |

|

BET surface area (m2/g): |

>800 m2/g |

>800 m2/g |

|

Pore Volume(cm3/g): |

0.6-0.75 |

0.5-0.8 |

|

Average Pore Size: |

About 2.7 nm |

About 2.7 nm |

|

bp: |

2230 °C(lit.) |

2230 °C(lit.) |

|

mp: |

>1600 °C(lit.) |

>1600 °C(lit.) |

This product is calcined and ready to use directly.

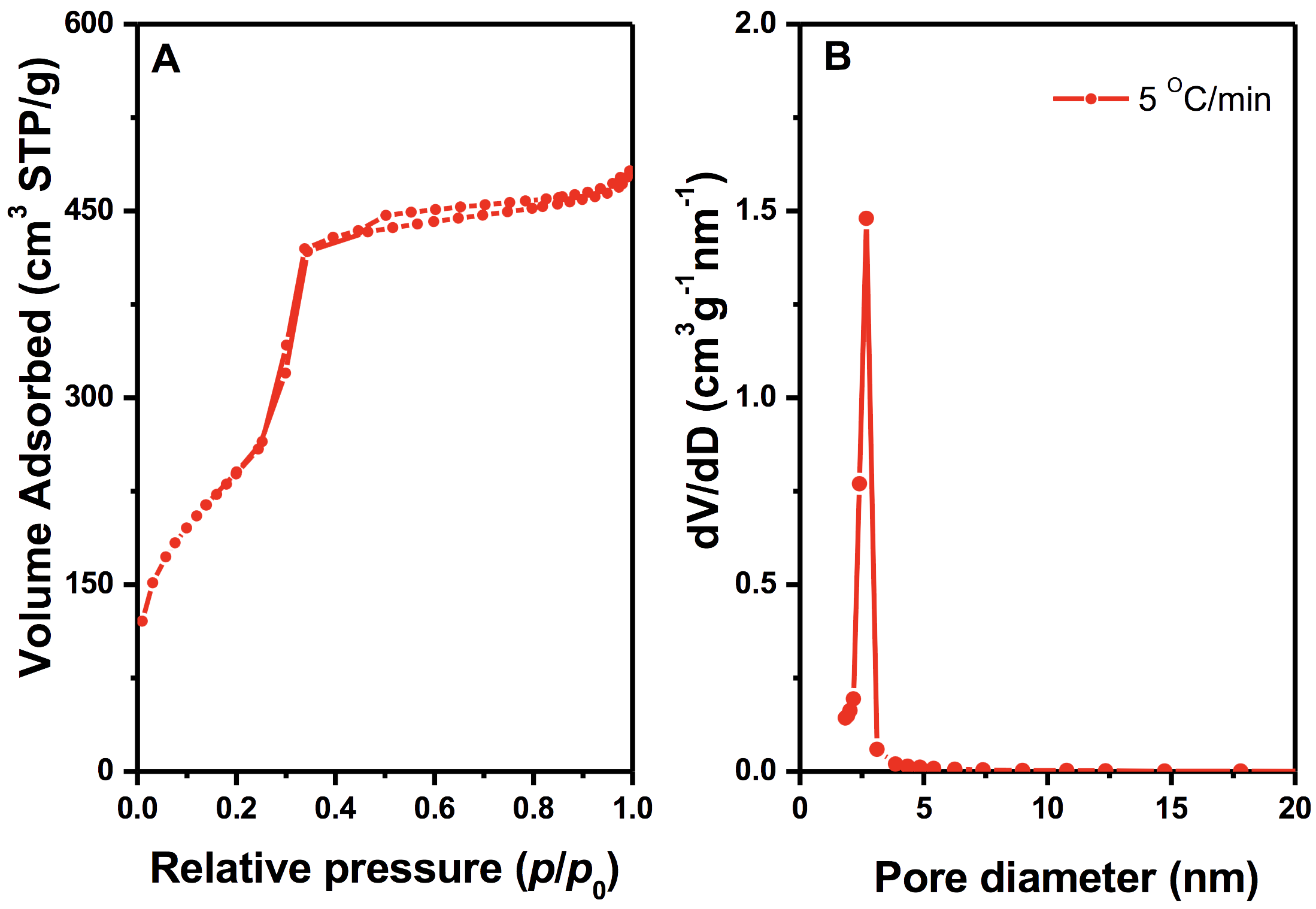

BET Analysis of ACS MCM-48 (Type A)

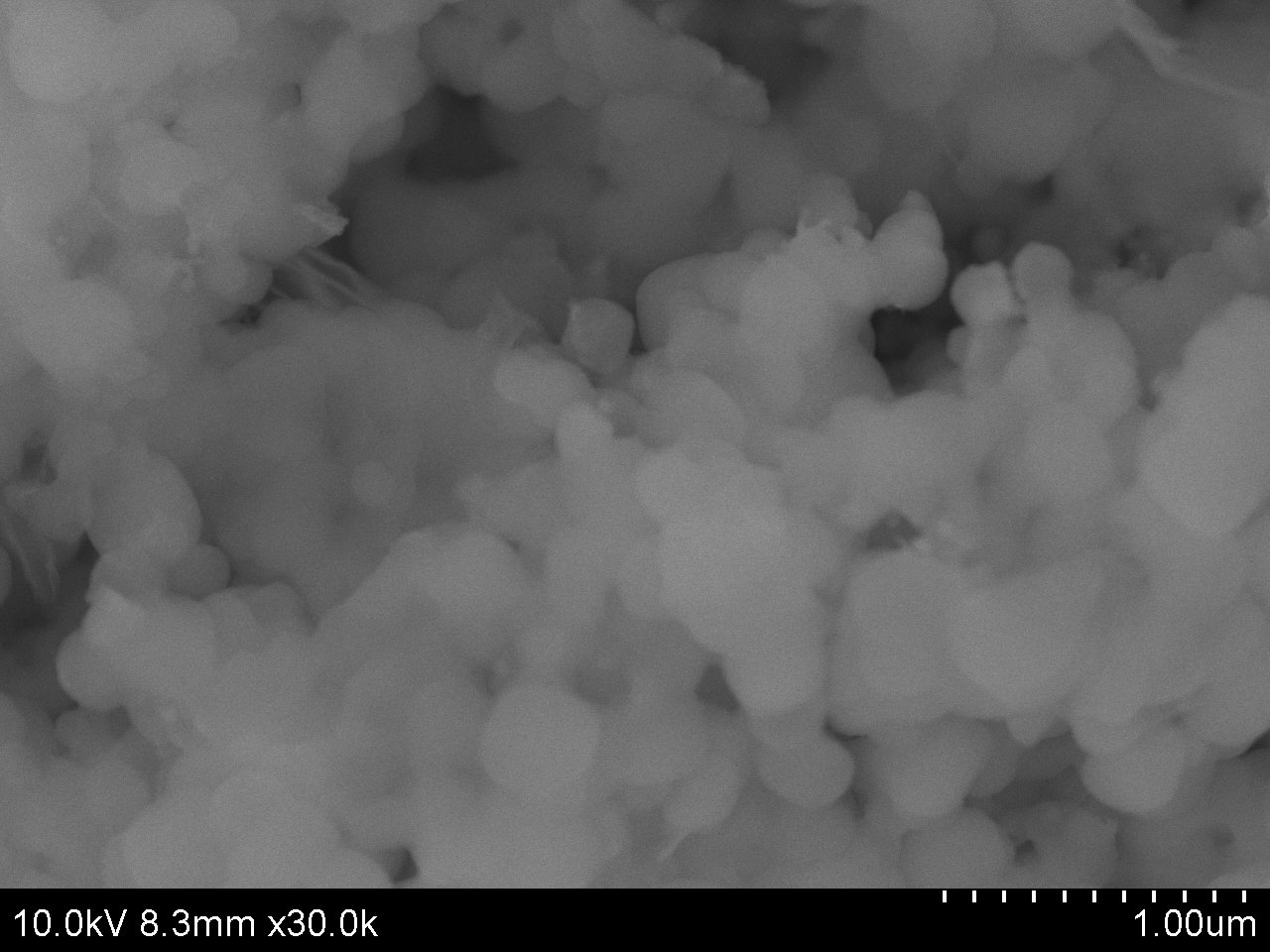

SEM Image of ACS Material MCM-48 (Type A)

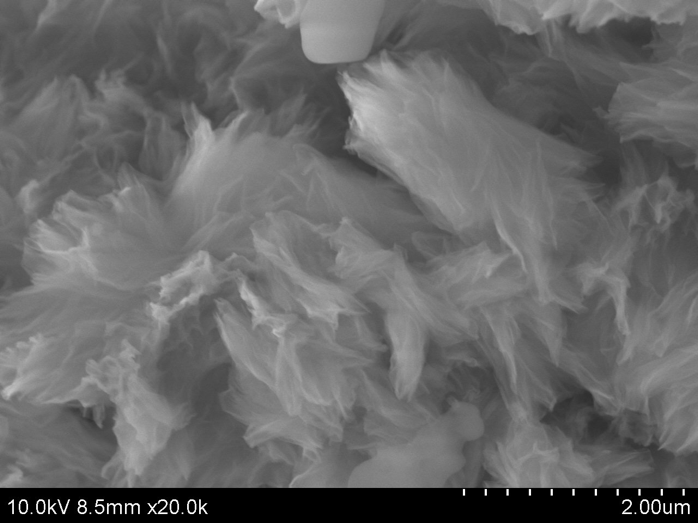

SEM Image of ACS Material MCM-48 (Type B)

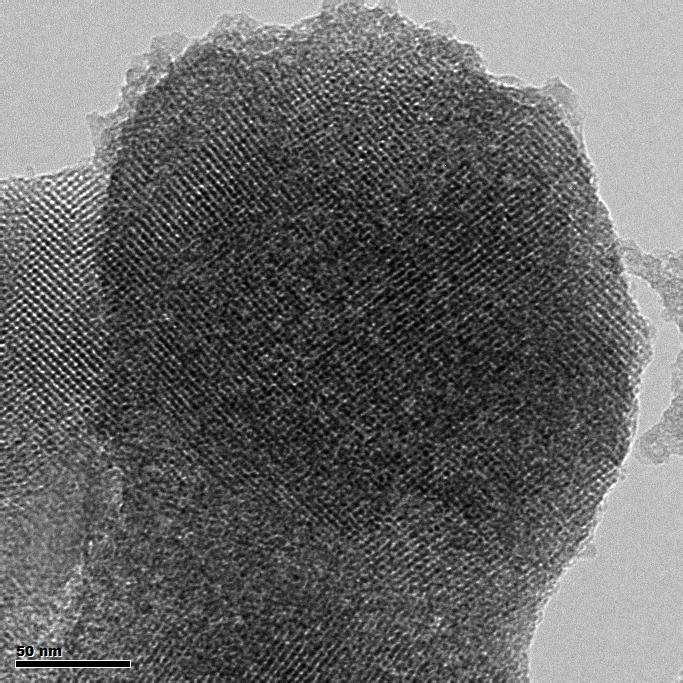

TEM Image of ACS Material MCM-48 (Type A)

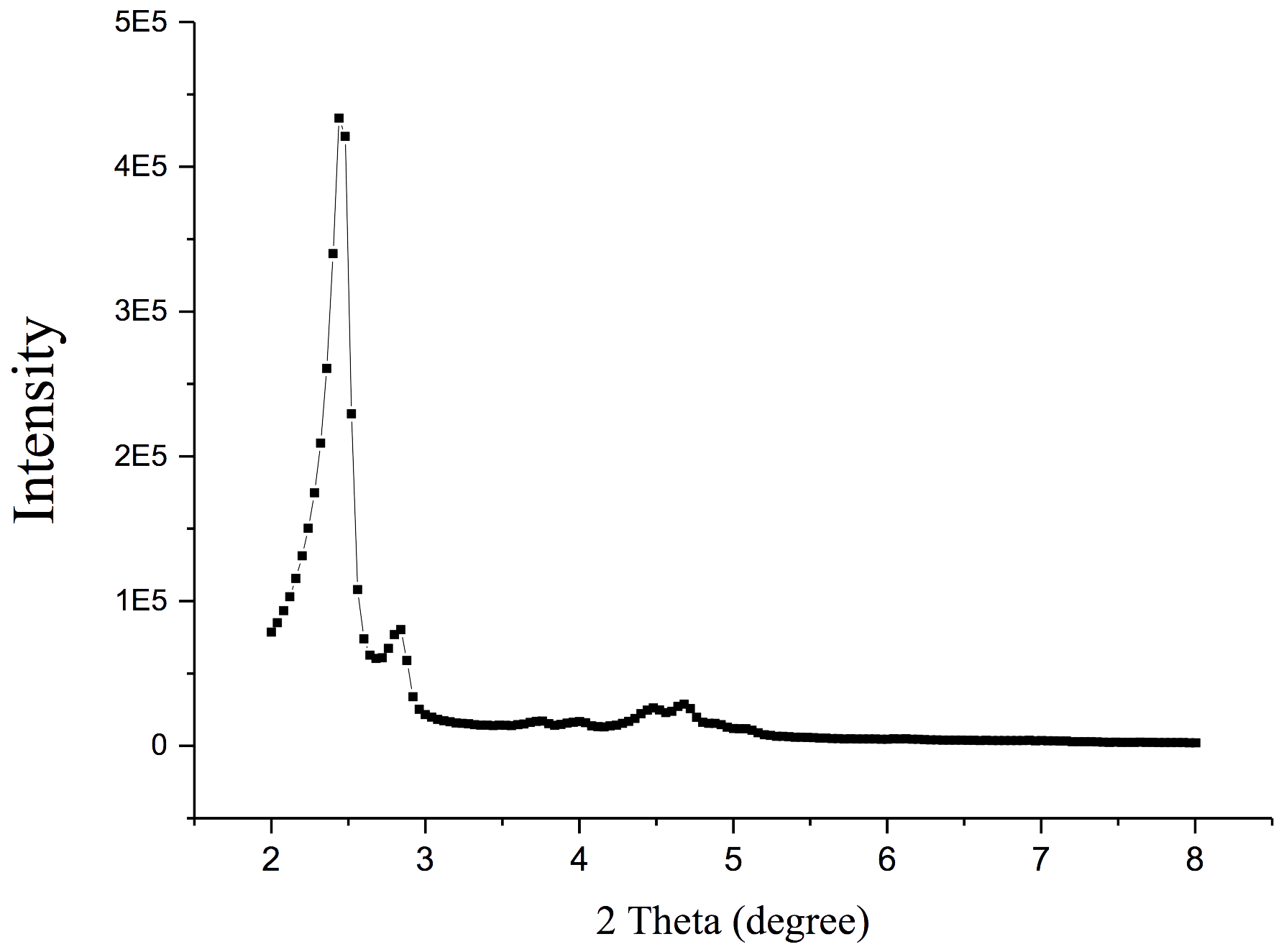

XRD Analysis of ACS Material MCM-48 (Type A)

3. Application Fields

Mesoporous silicas are inorganic materials having porous structures and find applications in chromatography, catalysis, drug delivery and imaging.

Disclaimer: ACS Material LLC believes that the information on our website is accurate and represents the best and most current information available to us. ACS Material makes no representations or warranties either express or implied, regarding the suitability of the material for any purpose or the accuracy of the information listed here. Accordingly, ACS Material will not be responsible for damages resulting from use of or reliance upon this information.

FAQ

1. What is the collapsing temperature of MCM-48? ·

About 750 degrees Celsius.

Research Citations of ACS Material Products

- Park, Sunghwan, et al. “3-Dimensionally disordered mesoporous silica (DMS)-Containing mixed matrix membranes for CO2 and non-CO2 greenhouse gas separations.” Separation and Purification Technology, vol. 136, 2014, pp. 286–295., doi:10.1016/j.seppur.2014.09.016.

- Martín, C.f., et al. “Wet impregnation of a commercial low cost silica using DETA for a fast post-Combustion CO 2 capture process.” Applied Energy, vol. 183, 2016, pp. 1705–1721., doi:10.1016/j.apenergy.2016.09.081.