HydroGenec™ Electrolyzer

Product Detail

Product Overview

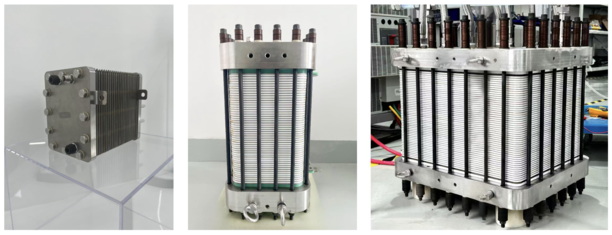

HydroGenec™ Electrolyzer 3kW, 30kW, and 200kW model

Product Features

The HydroGenec™ Electrolyzer, adopting Anion Exchange Membrane (AEM) technology and combining the advantages of both alkaline water electrolysis (ALK) and polymer electrolyte membrane (PEM), serves as the electrolysis cell, which is the core component of the AEM hydrogen production system. It is composed of end plates, collector plates, side frames, membrane electrodes, and sealing materials. This technology addresses key challenges in wind-powered hydrogen production. Compared to conventional ALK electrolyzer, the AEM hydrogen generation electrolyzer offers excellent safety and reliability.

Key Features

- Non-precious metal catalyst: Using non-precious metal catalysts, which are inexpensive and readily available, results in low costs.

- Anion exchange membranes offer a wide selection range: Anion exchange membrane water electrolysis does not require the use of expensive perfluorosulfonic acid membranes. The main categories include: polyarylether anion exchange membranes, aryl-ether-free anion exchange membranes, and other anion exchange membranes.

- Excellent gas tightness of anion exchange membrane: To overcome the problems of poor dynamic characteristics, lye corrosion and gas stringing safety of ALK electrolysis hydrogen production, the anion exchange membrane electrolysis technology adopts anion exchange membrane with good gas tightness, low resistance and low cost to replace the diaphragm of ALK, and the OH- in the lye passes through the anion exchange membrane to form the current circuit of the electrolyzer.

- The electrolyte is pure water or weak alkaline water: Anion exchange membrane electrolysis for water can use weak alkaline water or pure water as the electrolyte, alleviating the corrosion effects of strong alkaline solutions on the equipment.

Product Specifications

|

Product Name |

HydroGenec™ Electrolyzer |

||

|

Model |

Compact |

Pro |

Max |

|

SKU |

EHGEC001 |

EHGEP001 |

EHGEM001 |

|

Hydrogen Production Rate (Optional) |

0.2~1 Nm3H2/h |

2~10 Nm3H2/h |

20~40 Nm3H2/h |

|

Power (Optional) |

1~5 kW |

10~50 kW |

100~200 kW |

|

Energy Consumption |

4.3~4.8 kWh/Nm3 |

||

|

Operating Temperature |

60±5 ℃ |

||

|

Ambient Temperature |

5~40 ℃ |

||

|

Primary Hydrogen Purity |

Oxygen content < 500 ppm water content |

||

|

Power Fluctuation Range |

10%~110% ℃ |

||

|

Design Life |

15,000 hours |

||

|

Warranty |

1 year |

||

Disclaimer: ACS Material, LLC believes that the information in this website is accurate and represents the best and most current information available to us. ACS Material makes no representations or warranties either express or implied, regarding the suitability of the material for any purpose or the accuracy of the information contained within this document. Accordingly, ACS Material will not be responsible for damages resulting from use of or reliance upon this information.