-

What Are Nanoplatelets?

Jan 21, 2020 | ACS MATERIAL LLCGraphene Nanoplatelets

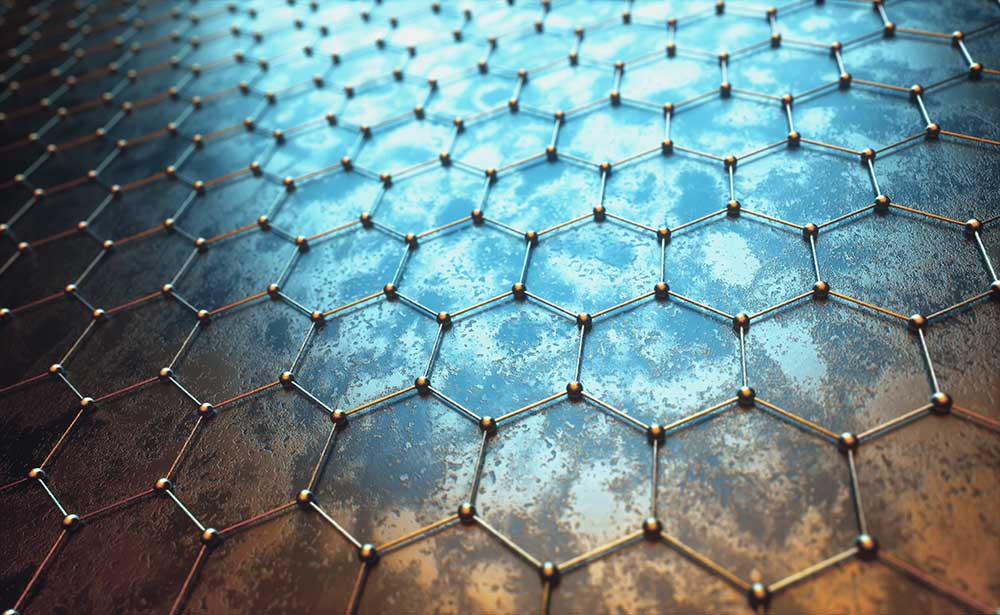

In 2004, two researchers at the University of Manchester, Andre Geim and Kostya Novoselov, used a piece of tape to separate a single-atom-thick layer of carbon from graphite and successfully transferred that layer onto a thin SiO wafer. This single layer of carbon atoms bonded together in a simple hexagonal structure is called graphene and its isolation earned Geim and Novoselov the 2010 Nobel Prize in physics. Since then, graphene has captured the imaginations of innovators, engineers, and researchers around the globe because of its unique and exciting combination of thermal, electrical, and mechanical properties. Dozens of new graphene-related nanoparticles are being discovered and developed that take advantage of graphene’s properties in new and exciting ways.

One of these new discoveries is graphene nanoplatelets (GNP), which are basically short stacks of platelet-shaped graphene sheets. Since graphene is obtained by exfoliating a single layer—or sheet—of carbon atoms from graphite, the obvious question is this: How are nanoplatelets different from graphite? The answer is all about stack size and sheet shape; while the distance between the individual graphene layers in GNP is similar to that of graphite, the size of the total stack of platelet-shaped sheets in GNP is much smaller. The number of atomic layers in these nanoplatelet stacks varies, but individual stacks have an overall thickness of between 1-10 nanometers and a lateral diameter of 1-15 micrometers. The platelet shape gives graphene nanoplatelets edges that can be easily chemically modified, enhancing their ability to be dispersed into a wide variety of composite applications. The size and shape of the nanoplatelets provide barrier properties and the graphene component makes them excellent conductors. When exfoliated graphene nanoplatelets are added to polymers, they add electrical and thermal conductivity, reduce gas permeability, and improve mechanical properties, such as tensile strength and surface hardness.

Adding graphene nanoplatelets has the potential to alter the function of the original material in a number of ways, including:

- Increasing thermal conductivity. The platelet shape gives materials lower thermal contact resistance at lower loading levels than standard carbon fibers or nanotubes, resulting in higher overall thermal conductivity.

- Lowering thermal expansion and increasing ultimate use temperatures. Polymers modified with GNPs function with more stability in thermally demanding environments.

- Increasing electrical conductivity. GNPs are highly conductive and improve the conductivity of most polymeric materials without affecting the base material’s aesthetic properties or harming surrounding tooling.

- Reducing permeability. GNPs are wider than they are thick, which makes materials more impermeable to gasses.

- Adding multiple benefits with one material. GNPs offer multifunctional benefits, making them a cost-effective additive for applications where multiple improvements are needed. For example, GNPs add both electrical conductivity and improved strength.

Endless Applications

Graphene nanoplatelets are rapidly moving from R&D labs to commercial applications. GNPs are being added to a wide range of materials such as cements, synthetic rubbers, paints, plastics, thermoplastic elastomers, adhesives, and many others. The following is just a small sample of the endless potential applications for graphene nanoplatelets:

- Ultracapacitor electrodes

- Lithium-ion batteries

- E-inks

- Thermal films and coatings

- Substrate for chemical sensors

- Concrete additive

- High-temperature lubricating materials

- Conductive rubbers and plastics

ACS Material is your source for high-quality graphene nanoplatelets. For prices, specific product details and specifications, please see our website or contact our team.

Related ACS Material Products: