-

Introduction to the LumioTech™ OLED Materials

Dec 23, 2024 | ACS MATERIAL LLCWhat are OLEDs?

- Organic Light-Emitting Diodes (OLEDs) represent a revolutionary advancement in display and lighting technology. At its core, OLEDs rely on organic compounds acting as a semiconductor to emit light when subjected to an electric current, a process known as electroluminescence. Unlike traditional displays, OLEDs do not require backlighting, enabling thinner, more flexible, and energy-efficient designs.

- The fundamental science of OLEDs lies in the layering of organic materials, typically sandwiched between an anode and a cathode. These materials, such as small molecules or polymers, are engineered to exhibit exceptional optical and electrical properties. When electrons and holes recombine in the emissive layer, light is emitted with high precision and vivid color reproduction. Advances in material science have further enhanced OLED performance, including increased brightness, extended lifespan, and reduced power consumption.

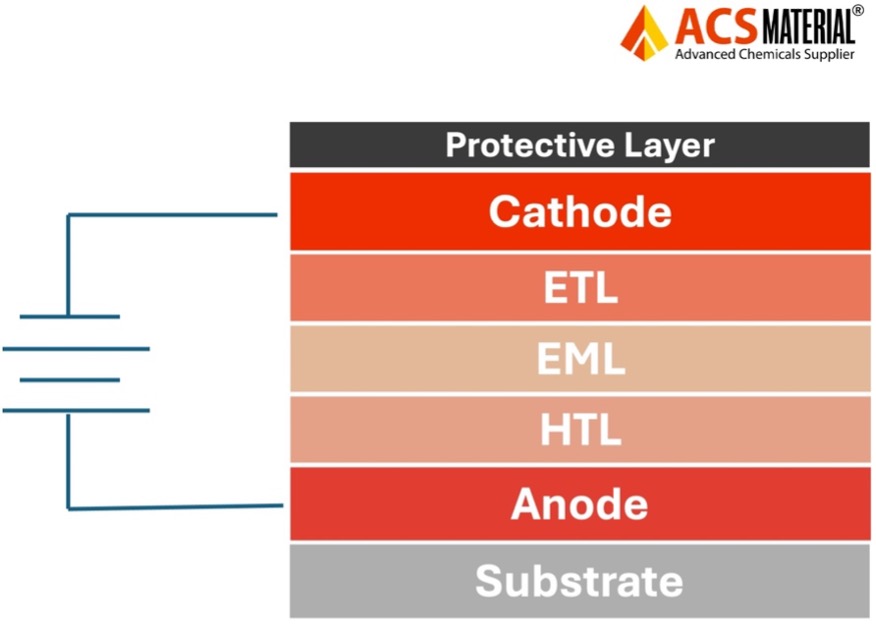

- The process flow of the OLED stack begins with the substrate, which supports the entire structure and is typically made of transparent glass or flexible plastic. On top of the substrate, the anode is deposited, serving as the hole injection layer. Holes from the anode are transported through the Hole Transport Layer (HTL) to the Emissive Layer (EML), where they recombine with electrons. Electrons are injected from the cathode, which is positioned as the bottom layer, and are transported via the Electron Transport Layer (ETL) to the emissive layer. To enhance efficiency, additional layers are often incorporated into the stack, such as the Hole Injection Layer (HIL) to improve hole injection and the Electron Injection Layer (EIL) to facilitate electron injection. These layers help optimize charge balance within the emissive layer, reducing energy losses and increasing overall performance. Finally, a protective layer is applied to shield the device from environmental factors like moisture and oxygen, ensuring durability and stability.

(Basic structure of an OLED)Why OLED Matters?

- The applications of OLED technology are vast and ever-growing. In consumer electronics, OLEDs dominate high-end displays for smartphones, televisions, and wearables, delivering superior contrast ratios and flexible form factors. Major companies like Apple, Samsung, LG, and Sharp are heavily investing in OLED technology, recognizing its potential to revolutionize display and lighting solutions. LG and Samsung lead in OLED TVs and displays, while Apple integrates OLEDs into its flagship devices like iPhones and Apple Watches. Sharp is also advancing OLED development for its devices, highlighting the technology's versatility. In the lighting industry, OLED panels are being explored for ambient and architectural lighting due to their uniform light emission and design flexibility. Beyond these, OLEDs are making strides in automotive displays, augmented reality (AR) devices, and even in the healthcare sector for innovative diagnostic tools. Research continues into more sustainable materials and production methods, aligning OLED development with global environmental goals, ensuring its relevance for decades to come.

ACS Material’s OLED LumioTech™

- OLEDs are transforming the display and lighting industries, offering exceptional visual performance, slim form factors, and energy efficiency. The foundation of this technology lies in the advanced materials that power OLED devices, and our portfolio of innovative compounds is designed to meet and exceed industry demands. Our cutting-edge technology for the blue emitter addresses the long-standing issue of degradation in transmission typical of conventional blue emitters. By significantly improving stability, this innovation enhances the longevity and reliability of OLED displays, ensuring superior performance over time.

- BTB:

- 4,4'-Bis-[2-(4,6-diphenyl-1,3,5-triazinyl)]-1,10-biphenyl

- Highly effective as an electron-transport material in OLEDs, and as a phosphorescent host material for green and red light-emitting diodes.

- CbBPCb:

- 3,3'-Di(9H-pyrido[2,3-b]-indol-9-yl)biphenyl

- Mainly used as a host material in OLEDs, phosphorescent host materials, semiconducting small molecules, and carboline derivatives.

- DMAC-DPS:

- 10,10′-(4,4′-Sulfonylbis(4,1-phenylene))bis(9,9-dimethyl-9,10-dihydroacridine

- A key role in OLED technology, functioning in various capacities such as an emitting layer material (EML), particularly as a blue-fluorescent dopant, and in thermally activated delayed fluorescence (TADF) and phosphorescent organic light emitting diodes (PHOLED) applications.

- mCPCN:

- 9-(3-(9H-Carbazol-9-yl)phenyl)-9H-carbazole-3-carbonitrile

- mCPCN stands out as a promising candidate within the OLED stack due to its unique structure, a high-triplet-energy phosphorescent host material, featuring a benzene core and two carbazole units (one containing a cyano group.

- Phen-TRZ:

- 2-(10H-Phenoxazine-10-yl)-4,6-diphenyl-1,3,5-triazine

- As a blue TADF emitter, Phen-TRZ plays a pivotal role in optimizing the performance and durability of modern OLED applications, making it indispensable for innovations in material science.

- PO-T2T:

- 2,4,6-Tris[3-(diphenylphosphinyl)phenyl]-1,3,5-triazine

- PO-T2T has emerged as a notable contender within the OLED stack. It is mainly used as an electron transport/hole blocking or an electron acceptor material in organic electronics.

- Organic Light-Emitting Diodes (OLEDs) represent a revolutionary advancement in display and lighting technology. At its core, OLEDs rely on organic compounds acting as a semiconductor to emit light when subjected to an electric current, a process known as electroluminescence. Unlike traditional displays, OLEDs do not require backlighting, enabling thinner, more flexible, and energy-efficient designs.