-

Introducing HydroGenec™ HPS & Electrolyzer: Advanced Hydrogen Production Solutions

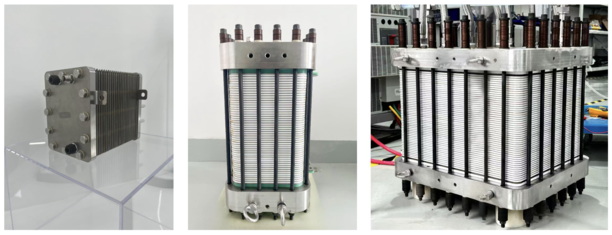

Mar 21, 2025 | ACS MATERIAL LLCWe are excited to introduce the HydroGenec™ Hydrogen Production System (HPS) and HydroGenec™ Electrolyzer, two cutting-edge technologies designed for efficient, scalable, and cost-effective hydrogen production. These modular systems leverage Anion Exchange Membrane (AEM) technology, providing superior performance, safety, and adaptability across various applications, from research and development to industrial-scale hydrogen production.

Key Features of HydroGenec™ HPS & Electrolyzer

- Modular and Scalable:Both systems can be customized to meet different hydrogen production demands, from small-scale research to large-scale industrial applications.

- High Safety and Reliability: Engineered with advanced membrane technology, ensuring excellent gas tightness and minimized corrosion risks.

- Cost-Effective Catalyst Solutions: Utilizes non-precious metal catalysts, reducing overall production costs while maintaining efficiency.

- Optimized Electrolyzer Performance: Features a stabilized membrane electrode structure and high-precision electric stack assembly for enhanced reliability.

- Flexible Electrolyte Options: The HydroGenec™ Electrolyzer can operate with pure water or weak alkaline water, reducing equipment corrosion compared to traditional ALK systems.

Model Variants and Applications Both the HydroGenec™ HPS and Electrolyzer come in three models to accommodate different hydrogen production requirements:

HydroGenec™ HPS: Hydrogen Production System

Compact Model (3kW) – Producing 0.6 Nm³/h of hydrogen, ideal for scientific research, teaching, R&D

Pro Model (30kW) – Generating 6 Nm³/h, suitable medium size projects

Max Model (200kW) – Delivering 40 Nm³/h, designed for industrial applications

HydroGenec™ Electrolyzer: AEM-Based Hydrogen Production

Compact Model – Producing 0.2~1 Nm³/h with 1~5 kW power consumption, ideal for small-scale hydrogen applications.

Pro Model – Generating 2~10 Nm³/h, suitable for medium-scale hydrogen production with 10~50 kW power usage.

Max Model – Capable of 20~40 Nm³/h, supporting large industrial applications with 100~200 kW power consumption.

The HydroGenec™ HPS and Electrolyzer are revolutionizing hydrogen production by combining AEM technology, modular scalability, and high efficiency. Whether you need a system for laboratory research or large-scale industrial applications, these technologies offer a reliable, sustainable, and cost-effective hydrogen generation solution.