-

Graphene: A Complete Chemical History

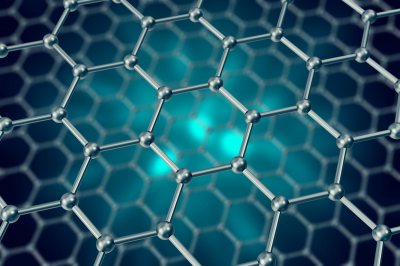

Sep 20, 2019 | ACS MATERIAL LLCGraphene is a two-dimensional sheet of densely packed carbon atoms arranged in a single layer. Its structure resembles a crystal honeycomb lattice or chicken wire fence of sorts. Graphene is a considerably large aromatic molecule in the flat polycyclic aromatic hydrocarbon family. It is made up of numerous carbon allotropes, like graphite, carbon nanotubes, and other fullerenes. In this blog we will discuss a bit more on the history of this fascinating material.

Introduction

Graphene is thought of as an infinite alternant of polycyclic aromatic hydrocarbon. The best graphene in the purest state consists solely of hexagonal cells. If pentagonal and heptagonal squares are present, then the material is considered defective. It takes a single pentagonal cell to turn the plane into a cone and inserting twelve pentagons morphs the graphene into the shape of a spherical fullerene. Several complex shapes of carbon nanobuds for example, can be made by adding controlled numbers of pentagons and heptagons. A single-walled carbon nanotube can sometimes be referred to as a graphene cylinder, and some have a half-sphere-shaped graphene cap, with 6 pentagons, at each end.

History

Single layers of graphite could only be observed in bulk materials via transmission microscopy, particularly in soot retrieved through chemical exfoliation at this point. Several attempts were made to create thin films of graphite by mechanical exfoliation, starting in 1990 and continuing into 2004, but the thinnest sheets made consisted of 50-100 layers. Although the results of these attempts did not produce graphene, the material gained considerable interest, and success in creating graphene as we know it today would come a short time later.In 1947, the existence of graphene was theorized by Philip R Wallace as an attempt to understand electronic properties of 3D graphite. He did not use the term “graphene”, but instead referred to it as a “single hexagonal layer.” Beginning in the 1970s single layers of graphite were grown epitaxially on other materials, creating a kind of “epitaxial graphene,” or free-standing graphene, a hexagonal lattice consisting of single-atom-thick bonded carbon atoms. The term “graphene” appeared for the first time in 1987 and was used to describe individual graphite sheets as one component of graphite intercalation compounds, or GICs (crystalline salts of intercalant and graphene). At this time, “graphene” was also used to describe carbon nanotubes, epitaxial graphene, and polycyclic aromatic hydrocarbons.

Chemical Discovery

In 2004, a Manchester group, led by Andre Geim, unexpectedly extracted single-atom-thick-crystallites from graphite. This ultimately proved the existence of true 2D crystals, such as graphene, which was at this point widely considered not able to exist in a flat state.

This discovery of graphene met skepticism until 2005, when the findings of Geim’s group were supported by that of another group helmed by Philip Kim at Columbia University. Kim’s group published an article in an issue of Nature stating that the findings of both groups proved beyond a reasonable doubt that the graphite layers they obtained exhibited the electronic properties described in Wallace’s theory from almost six decades prior.

Fabrication

One of the four common techniques for fabricating graphene is by chemical vapor deposition (CVD). The process involves introducing heated metal foil to different gases in order to deposit a layer of carbon on the metal surface. By tuning gas flow rates, exposure time, and temperature, you can control the CVD growth of graphene in terms of thickness and uniformity. Usually, graphene CVD forms a patchwork on the metal’s surface, with continuous single-layer areas spanning across and eventually overlapping one another in some areas.

The growth of graphene by CVD goes along with a transfer process that moves the graphene from the metal substrate to other substrates, in order to be measured and used for applications. Most methods use a polymer to transfer the film. Chemical vapor deposition (CVD) is aided by interactions between gas carbon precursors and a transition metal substrate. Copper is the most common transition substrate because of how easily carbon is deposited onto copper foil. The quality of graphene from CVD depositions on copper and other metals depends on the solubility of the carbon, and the electronic and crystal structure of the metal.

If you would like to learn more about graphene, contact ACS Material today!

Related ACS Material Products: