-

Carbon Nanomaterials

Dec 21, 2017 | ACS MATERIAL LLCCarbon nanostructures have expanded into a nice range of materials containing electrical and thermal conductivity along with other unique properties. Carbon nanomaterials, such as nanohorns, nanofibers and the more popular nanotubes, all have different shapes and features that set them apart from one another. Each nanomaterial incorporates graphene within its structure which adds to their distinctive characteristics and have been researched for use in electronics, sensors and batteries. Here, we will focus on the properties of these carbon materials measured on a nanometer scale and their promising applications.

Introduction

Carbon nanomaterials, such as carbon nanotubes, nanohorns and nanofibers, are covalently bonded by carbon atoms and have an sp2 hybridization. With a hexagonal pattern, high mechanical strength with thermal, optical and electrical properties, these materials owe much of their attributes to graphene.1 Although carbon nanomaterials have traits similar to that of graphene, their individual geometries and properties can be distinguished in their own right. Carbon nanotubes are the most popular of these materials making its mark in nanotechnology. However, more research has been conducted on other carbon-based nanomaterials with different diameters, lengths and chirality which has sparked many interests and have been applied to batteries, adsorption, transistors and so on.

Carbon Nanotubes

Carbon nanotubes (CNTs) are carbon sheets rolled into a cylindrical nanostructure that contains one or more layers of graphene with either open or closed ends. The structure and characteristic of a CNT can differ with varying lengths, diameters and number of walls. In fact, the length of the CNTs play an important role in composite properties as it was shown that longer CNTs displayed higher thermal and electrical conductivity; meanwhile, the mechanical strength and Young's Modulus remained the same with different lengths.2 Different types of CNTs are categorized as single-walled nanotubes (SWNTs), double-walled nanotubes (DWNTs) and multi-walled nanotubes (MWNTs) with diameters that can range anywhere between 0.8 to 2 nm, 2.75-4.78 nm and 5 to 50 nm, respectively.3,4

SWNTs display a one-atom-thick seamless cylindrical structure and exhibit a varying bandgap of 0-2 eV. DWNTs, on the other hand, are composed of two single-walled nanostructures concentric to each other that possess higher mechanical strength and thermal stability than its SWNT counterpart.5 Efforts in producing outer-wall selective functionalization schemes will potentially allow DWNTs be used in imaging and biological fields.6 MWNTs have multiple rolled layers of graphene in which its structure is often compared to the Russian Doll model with each decreasing size placed inside one another. The MWNT has a high aspect ratio and is considered to be a ballistic conductor, despite the many shells that may be expected to interact.4

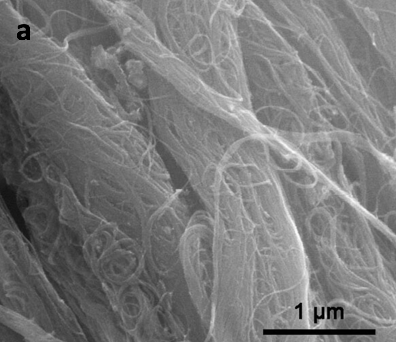

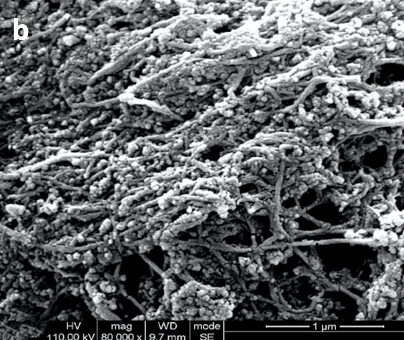

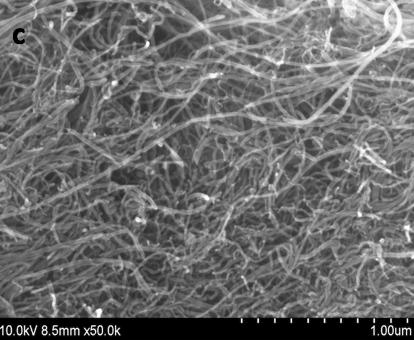

CNTs have been primarily synthesized with the chemical vapor deposition (CVD) but have been produced with other methods such as arc discharge and laser-ablation.6 Synthesizing well-aligned SWNTs was found to be a promising material in a number of applications such as transistors, sensors and additives for batteries. MWNTs have been appropriate as conductive polymers since it is highly conductive and for water filtration membranes due to its larger surface and strong mechanical strength.7 Meanwhile, the DWNTs can take on four distinct permutations from the metallic or semiconducting properties of their inner and outer walls that are typically used in thin film electronics and transistors; however, it is still quite a complicated system due to its polydiversity.5 ACS Material provides SWNTs, DWNTs and MWNTs with varying lengths, purity and functionalized options. In Figure 1 (a-c), the SEM images of ACS Material SWNTs, DWNTs and MWNTs are shown.

Figure 1. Typical SEM images of ACS Material a) SWNTs, b) DWNTs and c) amine-functionalized MWNTs.

Carbon Nanohorns

Carbon nanohorns (CNHs), or single-walled carbon nanohorns (SWNHs), are made up of a single graphene sheet that range between 2-5 nm in diameter and 40-50 nm in length. They typically possess closed cages but its structure may be opened to increase surface area and provide access to its interior cavity. When the opening of holes increased, it was found that the surface area goes from 330 to 1300 m2/g and pore volume expands from 0.2 to 0.9 mL/g.8 Nanohorns commonly have cone angles of approximately 20° and contain a conical front-tip segment followed by a short cylindrical nanotube section.9

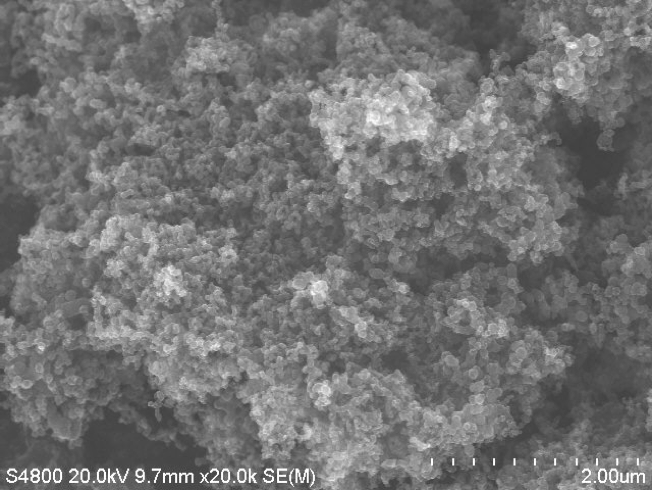

Unlike SWNTs, a large production rate of CNHs can be synthesized without a metal catalyst. CNHs have formed three types of roughly spherical aggregates based on different synthesis with an average diameter of 80-100 nm: dahlia-like a with long cone shaped tips, bud-like and seed-like where the horns are shorter in length. The nanohorns are commonly produced with either CO2 laser ablation of graphite at room temperature or the arc discharge method.8 CNHs share a similar chemistry to that of CNTs due to its elongated shape and has been considered to be a replacement in a number of fields such as energy conversion, drug delivery and supercapacitors.10 With high surface area and porosity, CNHs make reasonable gas storage, adsorption and sensor materials. ACS Material provides single-walled CNHs with an aggregate diameter of 80-100 nm and purity level greater than 97%.

Figure 2. Typical SEM image of ACS Material Carbon Nanohorns prepared by the arc discharge method.

Carbon Nanofibers

Carbon nanofibers (CNFs) are discontinuous filaments with diameters between 50-200 nm and varying lengths of up to 100 µm. This fibrous material contains stacks of graphene cones that has a high aspect ratio of about 250-2000 and a density of up to 2 g/cm3. Thermal and electrical conductivity (1950 W/m·K and 1 x 10-4 Ω·cm, respectively) are notable factors for CNF composites in polymers and other fields such as batteries and so on. Hollow core nanofibers have a single or double graphite layers stacked parallel or at a specific angle from the fiber axis. The stacked layers are nested with each other and have different structures such as bamboo-like, parallel and cup-stacked.11 Moreover, the different layering arrangements depend on the growth mechanism during the synthesis process.

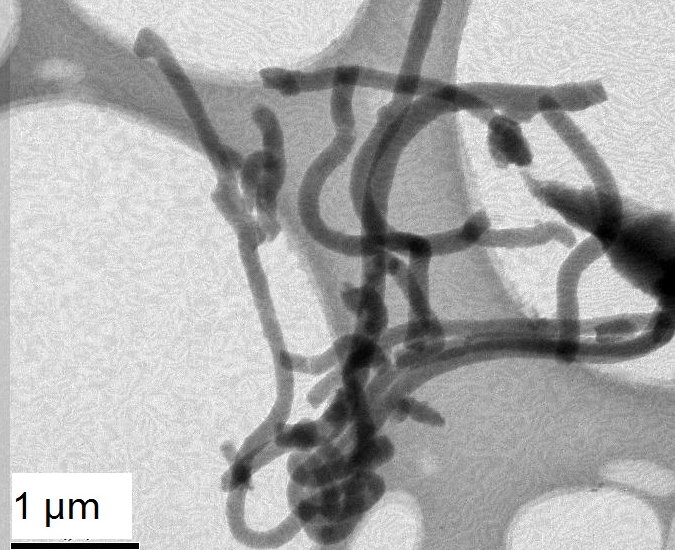

CNFs have been produced by electrospinning, hot filament-assisted sputtering and template-assisted methods although using a catalyst with the CVD method has been frequently employed.12 The remarkable properties of CNFs are dependent on their growth conditions. Based on these traits, CNFs have been used in semiconductor packing applications and building advanced capacitors. Since they exhibit large thermal conductivity, they can be combined as a filler into a matrix of another material such as solders or copper to be used in a thermal interface material.13 ACS Material provides CNFs that have been synthesized with the CVD method which has an outer diameter between 100-300 nm and length between 5-50 µm; the image of the product is shown in Figure 3, below.

Figure 3. A typical TEM image of ACS Material carbon nanofibers.

Conclusion

Adding to the unique attributes of graphene, carbon nanomaterials, such as CNHs and CNFs, have gained so much attention due to their properties. Significant advances in carbon nanomaterials have displayed a wide range of distinctive geometries and attributes that have led them towards potential uses in different applications. Although carbon nanotubes have been the most popular, other carbon-based nanomaterials with various structures have progressed through more research. Overall, these materials have promising uses and can provide a different alternative in many applications in the future.

ACS Materials Products:

Carbon Nanotubes:

Carbon Nanohorns:

Carbon Nanofibers:

References

- Chen, Tao, and Liming Dai. “Carbon nanomaterials for high-Performance supercapacitors.” Materials Today, vol. 16, no. 7-8, 2013, doi:10.1016/j.mattod.2013.07.002.

- Wang, Xin, et al. “Effect of carbon nanotube length on thermal, electrical and mechanical properties of CNT/Bismaleimide composites.” Carbon, vol. 53, 2013, pp. 145–152., doi:10.1016/j.carbon.2012.10.041.

- Fujisawa, Kazunori. “A Review of Double-Walled and Triple-Walled Carbon Nanotube Synthesis and Applications.” Applied Sciences, 2016, doi: 10.3390/app6040109.

- Schoenenberger, Christian, and Laszlo Forro. “Physics of multiwalled carbon nanotubes.” Conference: Physics, Chemistry and Application of Nanostructures - Reviews And Short Notes To Nanomeeting, 2001, doi: 10.1142/9789812810076_0010 .

- Shen, Cai, et al. “Double-Walled carbon nanotubes: Challenges and opportunities.” Nanoscale, vol. 3, no. 2, 2011, pp. 503–518., doi:10.1039/c0nr00620c.

- Green, Alexander A., and Mark C. Hersam. “Properties and Application of Double-Walled Carbon Nanotubes Sorted by Outer-Wall Electronic Type.” ACS Nano, vol. 5, no. 2, 2011, pp. 1459–1467., doi:10.1021/nn103263b.

- Eatemadi, Ali, et al. “Carbon nanotubes: properties, synthesis, purification, and medical applications.” Nanoscale Research Letters, vol. 9, no. 1, 2014, p. 393., doi:10.1186/1556-276x-9-393.

- Ma, Lining, et al. “Fabrication and Water Treatment Application of Carbon Nanotubes (CNTs)-Based Composite Membranes: A Review.” Membranes, vol. 7, no. 1, 2017, p. 16., doi:10.3390/membranes7010016.

- Yudasaka, Masako, et al. “Single-Wall Carbon Nanohorns and Nanocones.” Topics in Applied Physics Carbon Nanotubes, 2007, pp. 605–629., doi:10.1007/978-3-540-72865-8_19.

- Karousis, Nikolaos, et al. “Structure, Properties, Functionalization, and Applications of Carbon Nanohorns.” Chemical Reviews, vol. 116, no. 8, 2016, pp. 4850–4883., doi:10.1021/acs.chemrev.5b00611.

- Al-Saleh, Mohammed H., and Uttandaraman Sundararaj. “Review of the mechanical properties of carbon nanofiber/Polymer composites.” Composites: Part A, 2011, doi:10.1016/j.compositesa.2011.08.005.

- Zou, Guifu. “Carbon nanofibers: Synthesis, characterization, and electrochemical properties.” Science Direct, vol. 44, no. 5, 2013, doi:10.1016/j.carbon.2005.10.035.

- Desmaris, Vincent, et al. “Examining Carbon Nanofibers: Properties, growth, and applications.” IEEE Nanotechnology Magazine, vol. 9, no. 2, 2015, pp. 33–38., doi:10.1109/mnano.2015.2409394.