3D Graphene on Nickel/Copper Foam

3D Multilayer Graphene on Nickel/Copper Foam

Product Detail

CAS No.: 7782-42-5 (graphene), 7440-02-0 (nickel)

| Ni thickness | 1mm |

| Pore density | 110ppi |

| Porosity | 98% |

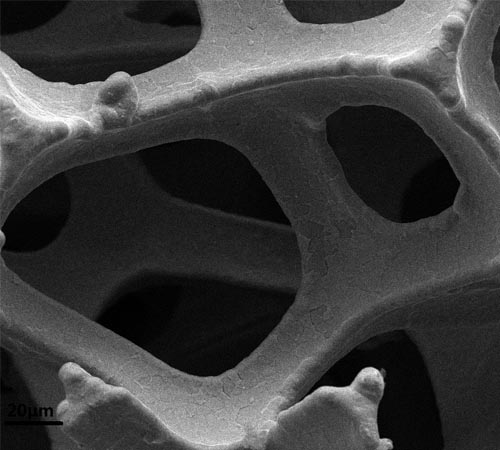

SEM Image of 3D Graphene on Nickel Foam

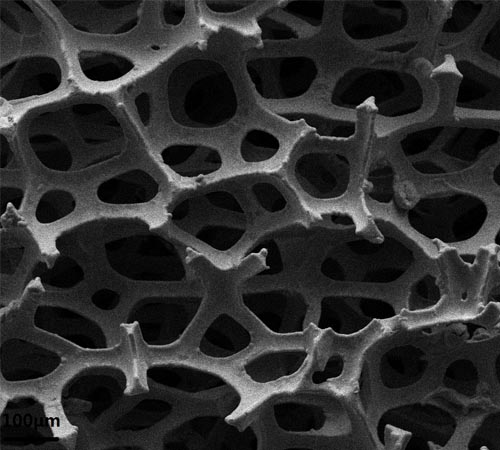

SEM Image of 3D Graphene on Nickel Foam

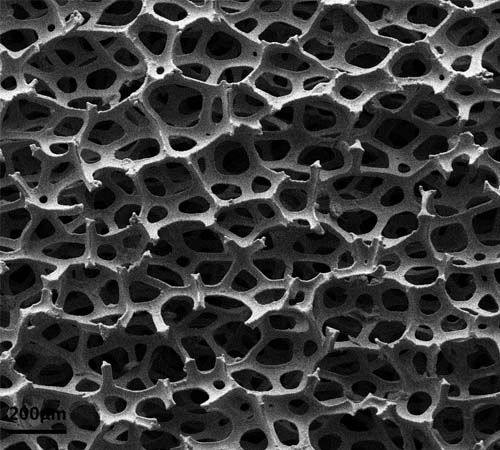

SEM Image of 3D Graphene on Nickel Foam

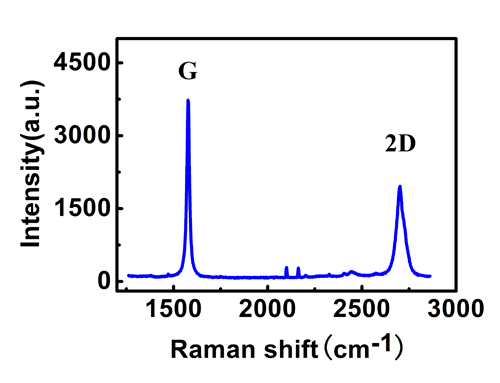

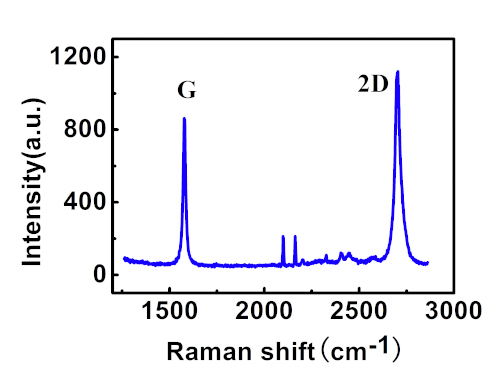

Raman Image of 3D Graphene on Nickel Foam (One point)

Raman Image of 3D Graphene on Nickel Foam (another point)

Disclaimer: ACS Material LLC believes that the information on our website is accurate and represents the best and most current information available to us. ACS Material makes no representations or warranties either express or implied, regarding the suitability of the material for any purpose or the accuracy of the information listed here. Accordingly, ACS Material will not be responsible for damages resulting from use of or reliance upon this information.

FAQ

1. What is the average pore size?

The average pore size is about ~0.2mm

2. What are the number of layers of graphene?

The graphene layers are from a few layers to dozens of layers. Generally if the layers are too thin, then it will collapse.

3. Has this foam used for the synthesis of metal-graphene composites?

Yes, this foam has been used and can do metal-graphene composite preparation, but kindly note that many specific experiments may need their own assessment depending on the application.

Research Citations of ACS Material Products

- Lin, Huan, et al. “Significantly reduced thermal diffusivity of free-Standing two-Layer graphene in graphene foam.” Nanotechnology, vol. 24, no. 41, 2013, p. 415706., doi:10.1088/0957-4484/24/41/415706.

- Asfaw, Habtom D., et al. “Nanosized LiFePO4-Decorated emulsion-Templated carbon foam for 3D micro batteries: a study of structure and electrochemical performance.” Nanoscale, vol. 6, no. 15, 2014, pp. 8804–8813., doi:10.1039/c4nr01682c.

- Leeuwner, M. J., et al. “Novel Graphene Foam Microporous Layers for PEM Fuel Cells: Interfacial Characteristics and Comparative Performance.” Fuel Cells, vol. 15, no. 6, Mar. 2015, pp. 790–801., doi:10.1002/fuce.201500031.

- Nieto, Andy, et al. “Graphene reinforced metal and ceramic matrix composites: a review.” International Materials Reviews, vol. 62, no. 5, 27 Oct. 2016, doi:10.1080/09506608.2016.1219481.